snbi vickers hardness test|vickers hardness scale chart : commercial Fig. 4 shows the hardness of the SnBi samples been tested at 0.05 s −1 strain rate. The two pure samples (Sn and Bi) have much lower hardness as compared to the alloy . 23 de set. de 2009 · Assistir Modern Family - Família Moderna de graça em HD, .

{plog:ftitle_list}

Descubra a emoção dos jogos online no Tigrinho777. Registre-se agora para uma jornada repleta de segurança e entretenimento.

what is vickers hardness

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 . Fig. 4 shows the hardness of the SnBi samples been tested at 0.05 s −1 strain rate. The two pure samples (Sn and Bi) have much lower hardness as compared to the alloy .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .

site kalsi.com seal testing

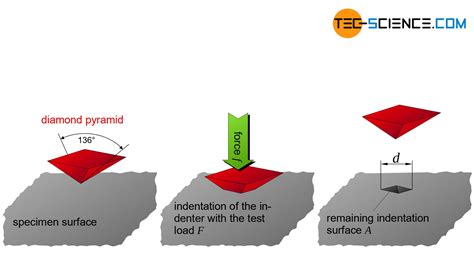

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface.1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:Vickers Hardness Testing. Microhardness testing of metals, ceramics, and composites is useful for a variety of applications for which 'macro' hardness measurements are unsuitable: testing very thin materials like foils, measuring individual microstructures, or measuring the hardness gradients of a part along the cross section. .

The Wilson VH1150 Macro Vickers Hardness Tester is the ultimate macro-Vickers hardness tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection and a seamlessly integrated motorized turret in . Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over .

The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the last 90 years, upgrades to the equipment used to perform the test have expanded its use and accuracy. The Vickers hardness number is the load (test .Explanation: Vickers hardness test has a disadvantage of large floor standing machine. It can overcome the limitations of the Brinell test. For example, hardness above 450 BHN can be measured. Sanfoundry Certification Contest of the Month is Live. 100+ Subjects. Participate Now! 6. Why Brinell and Vickers hardness test results show similarities?

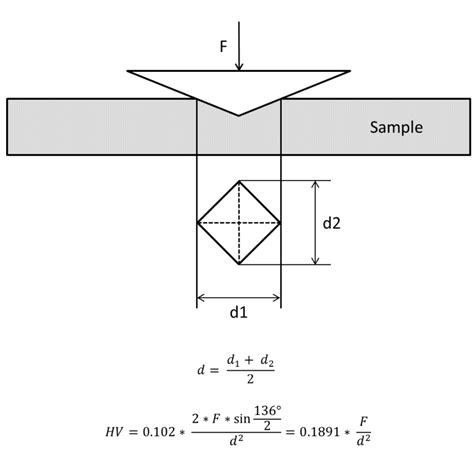

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.]Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . Standardized Testing: Vickers hardness testing is commonly used in standardized testing methods, making it suitable for comparing hardness values across different materials. Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples.

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.Vickers hardness test can contribute to material certification, compliance with industry standards, and ensuring the integrity of manufactured products. Vickers hardness testing is a versatile and widely adopted technique that provides .

Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is .

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. .

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .The FALCON 500 offers a leading technology base for manual, automatic or fully automated testing of Micro and Macro Vickers, Knoop or Brinell assignments. With a wide choices of test force configurations, answering any possible imagination, the FALCON 500 can be completed with fully integrated hardware options to assure a match with the . A Vickers hardness testing machine can share the same components and layouts as Brinelle and Rockwell testers. However, what makes it unique is the use of a universal indenter which allows for ease of maintenance. Also, the Vickers tester measures hardness by the Vickers Hardness Value (symbolized as HV) or the Diamond Pyramid Hardness Value .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384). Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's hardness. The Vickers test employs a pyramid-shaped diamond indenter with a square base angle of 136 degrees. This indenter is pressed into the material under a known . Our work pioneers systematic study bridging the gap between NI hardness and σUTS for 55 ± 2.5 wt% SnBi alloys. NI to vickers hardness linear correlation coefficient, C1, is found to be greater than 1.25. The Tabor factor, k, is found to be consistently greater than 3. . Sawa T. Correlation between nanoindentation test result and vickers .

Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F for a time interval of, say, 10-15 s.During this interval, the material undergoes plastic deformation, which you will measure after unloading the material specimen.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

The Vickers hardness test can be applied for micro-testing. Knoop: Specifically used to test thin or brittle materials, as it gives a meaningful reading with a shallow indentation. It uses an elongated pyramid to make the impression, with the measurement of the long diagonal used to calculate the Knoop hardness.

site kalsi.com seal testing and support

11 de jun. de 2017 · Melhores momentos: Inglaterra 1 x 0 Venezuela na decisão da Copa do Mundo sub 20. Um gol de Calvert-Lewin, revelação do Everton, aos 35 minutos da final garantiu à Inglaterra a vitória sobre a .

snbi vickers hardness test|vickers hardness scale chart